At Wafangdian JinYu Bearing Manufacturing Co.,Ltd, we engineer bearings through a rigorous 8-stage process, combining advanced metallurgy and smart manufacturing. From raw steel selection to final packaging, every step ensures ISO SO 9001:2015-certified quality. Below, we visualize our production flow with key stages and technologies.

1. Raw Material Preparation

Process:

- Material Selection: High-grade alloy steel (e.g., AISI 52100) tested for carbon content and impurities. Our Bearing Steel Procurement Sources

- Cutting: Steel rods are cut to precise lengths using CNC saws.

2. Forging

Process:

- Heating: Billets heated to 1,100–1,200°C in induction furnaces.

- Shaping: Hydraulic presses mold steel into ring blanks.

- Cooling: Controlled air cooling to eliminate internal stresses.

3. Bainitic Quenching

Process:

- Austenitizing: Steel heated to 850°C in salt baths.

- Bainite Formation: Rapid oil cooling creates a tough, wear-resistant microstructure.

- Tempering: Stabilizes bainite at 180°C for 2 hours.

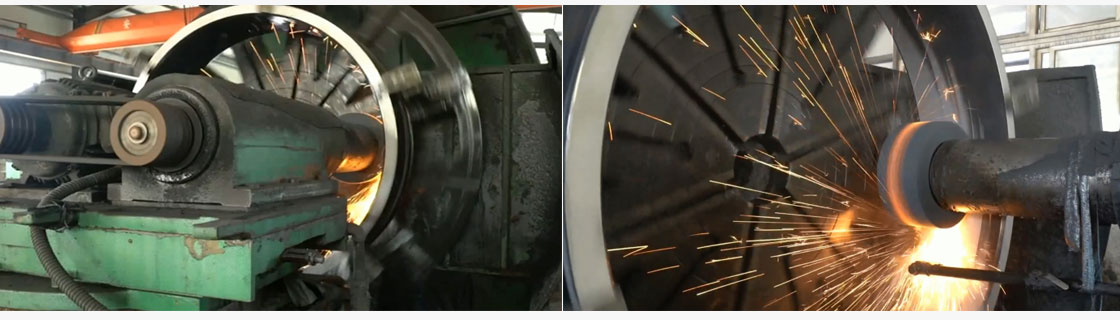

4. Grinding

Process:

- Rough Grinding: Cylindrical grinders shape outer/inner diameters.

- Precision Grinding: Diamond wheels finish raceways with ±0.005mm tolerance.

5. Component Machining

Process:

- Cage Production: Stamped or machined brass/steel retainers.

- Roller Fabrication: Precision-turned balls or rollers.

6. Assembly

Process:

- Cleaning: Ultrasonic degreasing in alkaline solution.

- Lubrication: Grease injection to specified fill levels.

- Final Assembly: Rollers, cages, and races aligned via CNC fixtures.

Bearing assembly process

Bearing assembly process7. Quality Inspection

Process:

- Dimensional Checks: Laser micrometers verify tolerances.

- Rotation Test: Spin at 20,000 RPM to detect imbalance.

- Load Testing: Simulate operational stress for 500,000 cycles.

Unrivaled Precision: Wafangdian JinYu Bearing Manufacturing Inspection Workshop

8. Packaging & Storage

Process:

- Anti-Rust Treatment: VCI paper + desiccant packets.

- Sealing: Vacuum-packed in UV-resistant film.

Brearing Packaging & Storage

Brearing Packaging & Storage

Conclusion

WJY Bearing’s 8-step process combines material science, precision machining, and rigorous QA to deliver bearings exceeding ISO 9001 standards. From smart quenching systems to automated assembly lines, every stage ensures reliability for industries like aerospace and wind energy.