Product Overview

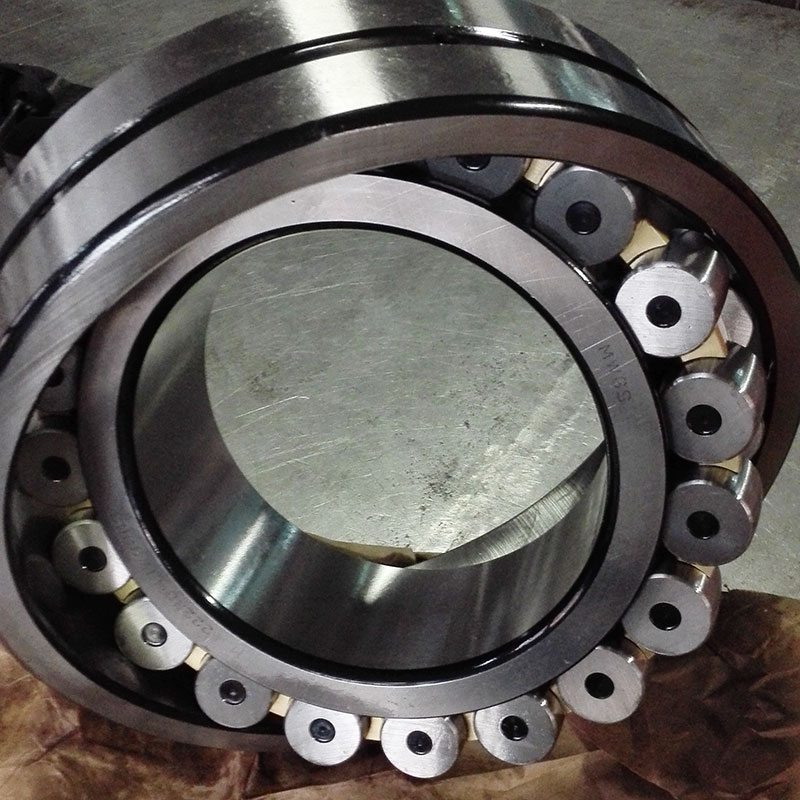

The Spherical Roller Bearing 222 Series is a high-performance industrial bearing solution designed to meet the demanding requirements of heavy machinery and mining equipment. With its unique self-aligning design and advanced manufacturing technology, this series offers exceptional load capacity and operational reliability in harsh environments.

100-400mm bore

Design Features

Self-aligning Capability

One of the most prominent features of the 222 series spherical roller bearings is its self-aligning function. The spherical outer ring raceway and two rows of barrel-shaped rollers enable the bearing to automatically compensate for shaft misalignment between the shaft and the housing. This feature ensures smooth operation even when there are angular errors, typically up to 1.5° – 2° under normal loads, reducing the risk of premature failure due to misalignment.

Robust Construction

These heavy duty bearings are constructed with high-quality bearing steel. The inner and outer rings are precisely machined to provide a smooth running surface for the rollers. The large-diameter rollers are designed to increase the contact area with the raceways, significantly enhancing the bearing’s load-carrying capacity. The cages, usually made of high-strength steel or brass, are engineered to maintain the correct separation and guidance of the rollers, ensuring stable operation at high speeds.

Performance Advantages

High Load Capacity

The Spherical Roller Bearing 222 Series excels in handling heavy radial loads and moderate axial loads in both directions. It can withstand substantial radial loads, making it an ideal choice for applications where the equipment is subjected to high-stress conditions. For example, in mining crushers, the 222 series bearings can support the massive weight of the rotating parts and the impact forces generated during the crushing process.

Excellent Vibration and Shock Resistance

Thanks to its robust design and high-quality materials, this series of bearings offers excellent resistance to vibration damping and shock. This makes it suitable for use in industries such as construction machinery, where equipment often operates in harsh and uneven environments. The bearings can effectively dampen vibrations, ensuring the stability of the machinery and reducing the wear and tear on other components.

Low Friction and High Efficiency

Advanced manufacturing techniques and precision-ground surfaces result in low friction within the bearing. This not only reduces energy consumption but also improves the overall efficiency of the machinery. In industrial motors, the use of 222 series bearings can lead to significant energy savings over time, contributing to a more sustainable operation.

222 Series Technical Specifications & Product Data

Standard Technical Specifications

All 222 Series bearings are manufactured to standard specifications, with comprehensive customization options available to meet specific application requirements.

- Material: GCr15 Bearing Steel (AISI 52100 Equivalent)

- Radial Clearance: C3 Group (Greater than Normal)

- Precision Class: P0 (ABEC 1 Equivalent)

- Lubrication Features: One annular groove and three lubrication holes on outer ring (W33 designation)

Our 222 Series Product Data

Below is our comprehensive selection of 222 Series spherical roller bearings, showcasing our most popular models and specifications. This range represents our standard production series, with additional sizes and custom configurations available upon request.

| Bearing No. | Dimensions d×D×B (mm) |

Cage Type | Dynamic Load Cr (kN) |

Static Load Cor (kN) |

Weight (kg) |

Inquiry |

|---|---|---|---|---|---|---|

| 22220 | 100×180×46 | CA CC MB | 277 | 425 | 5.18 / 5.02 | |

| 22222 | 110×200×53 | CACCMB | 345 | 545 | 7.43 / 7.15 | |

| 22224 | 120×215×58 | CA CC MB | 445 | 735 | 10.3 / 10.1 | |

| 22226 | 130×230×64 | CA CC MB | 490 | 805 | 12.4 / 12.1 | |

| 22228 | 140×250×68 | CA CC MB | 560 | 930 | 16.2 / 15.7 | |

| 22230 | 150×270×73 | CA CC MB | 630 | 1050 | 18.7 / 18.2 | |

| 22232 | 160×290×80 | CA CC MB | 750 | 1300 | 24.6 / 24.3 | |

| 22234 | 170×310×86 | CA CC MB | 845 | 1450 | 26.8 / 26.1 | |

| 22236 | 180×320×86 | CA CC MB | 895 | 1550 | 29.4 / 29.1 | |

| 22238 | 190×340×92 | CA CC MB | 865 | 1620 | 37.4 / 37 | |

| 22240 | 200×360×98 | CA CC MB | 1100 | 1950 | 44.7 / 44.1 | |

| 22244 | 220×400×108 | CA CC MB | 1350 | 2400 | 63.5 / 63.1 | |

| 22248 | 240×440×120 | CA CC MB | 1640 | 1820 | 85 / 84.8 | |

| 22252 | 260×480×130 | CA CC MB | 1900 | 3600 | 106 / 105 | |

| 22256 | 280×500×130 | CA CC MB | 1990 | 3600 | 118 / 117 | |

| 22260 | 300×540×140 | CA CC MB | 2310 | 4300 | 138 / 137 | |

| 22264 | 320×580×150 | CA CC MB | 2490 | 4550 | 175 / 174 | |

| 22268 | 340×620×165 | CA MB | 2650 | 5050 | 225 | |

| 22272 | 360×650×170 | Standard | 3630 | 6200 | 253 | |

| 22276 | 380×700×175 | CA | – | – | 307 | |

| 22280 | 400×720×185 | CA MB | 4400 | 7400 | 337 |

Cage Type Explanation

Copper Alloy Cage

Excellent for high temperature and high speed applications

Steel Cage

High strength, suitable for heavy load conditions

Machined Brass Cage

Superior guidance, ideal for high precision applications

Custom Cage Options: Other cage types available upon request, including E-type, EAE4-type, and other specialized designs for specific application requirements.

Complete 222 Series Technical Catalog

Download detailed specifications for all 222 series models (100-400mm bore) including installation guidelines, load calculations, and technical drawings.

Industrial Applications

Mining Industry

In the mining industry, the 222 series is widely used in equipment such as ball mills, conveyors, and crushers. Ball mills require bearings that can handle the heavy loads and vibrations generated during the grinding process. The self-aligning feature of the 222 series ensures smooth operation, reducing downtime and maintenance costs.

Metallurgical Industry

Metallurgical equipment, such as continuous casters and rolling mills, operates under extremely high loads and harsh conditions. The Spherical Roller Bearing 222 Series can withstand these demanding conditions, providing reliable support for the rotating parts of the equipment. Its high load-carrying capacity and shock-resistance properties are crucial for maintaining the continuous operation of the production line.

Construction Machinery

In construction machinery like excavators, loaders, and bulldozers, the 222 series bearings play a vital role in supporting the rotating components. These machines often operate in rough terrains, and the bearings need to be able to handle misalignments caused by the uneven movement of the equipment. The 222 series bearings’ self-aligning and shock-resistance capabilities make them well-suited for such applications.

Quality Assurance

We adhere to strict quality control standards in the production of the Spherical Roller Bearing 222 Series. Every bearing undergoes rigorous inspection and testing processes, from the raw material stage to the final product. We are certified to international quality management systems such as ISO 9001, ensuring that our products meet the highest quality requirements. Our commitment to quality means that you can rely on our 222 series bearings for long-term, trouble-free operation.