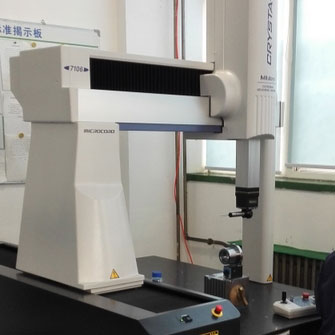

Precision inspection of bearing components using a Coordinate Measuring Machine

1. Raw Material & Blank Inspection

At the initial stage of bearing manufacturing, CMM is used to screen qualified blanks and avoid waste in subsequent processing:

Inspect basic dimensions of blanks (outer diameter, inner diameter, height, etc.)

Check basic geometric defects (ellipticity, end face flatness, etc.)

Ensure sphericity or cylindricity accuracy of rolling element blanks

2. In-Process Precision Control

After key manufacturing processes, CMM verifies processing quality and corrects deviations in a timely manner:

Turning Process Inspection

Inspect inner hole, outer diameter of bearing rings and initial position of raceways to meet process requirements.

Grinding Process Inspection

Focus on inspecting raceway radius, roundness and positional accuracy to ensure micron-level tolerance control.

3. Final Product Inspection

Comprehensive precision verification is conducted before bearings leave the factory:

- Key dimension inspection (inner diameter, outer diameter, rolling element diameter, etc.)

- Geometric tolerance inspection (coaxiality, parallelism, circular runout, etc.)

- Assembly clearance inspection (radial and axial clearance)

4. Failure Analysis & Process Improvement

• Identify process issues (e.g., grinding deviations, inaccurate fixture positioning)

• Provide data support for production process optimization to reduce subsequent failure risks

Conclusion

Through full-process precision inspection, Coordinate Measuring Machines (CMM) ensure every step of bearings—from blanks to finished products—meets precision requirements. It is not only a tool for quality control, but also a key equipment to drive continuous improvement of bearing manufacturing processes and enhance product competitiveness.