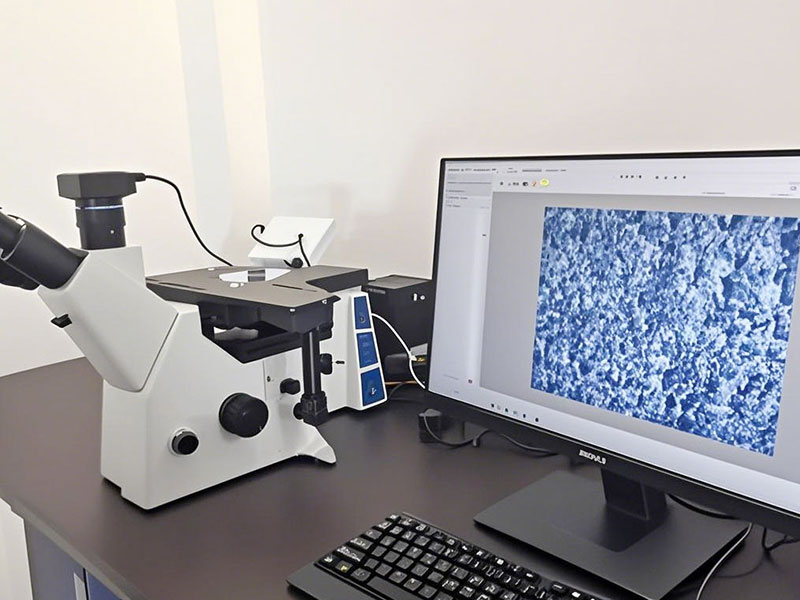

Observing the microstructure of bearing steel under a metallurgical microscope

In the bearing manufacturing process, product quality directly determines the operational precision and service life of equipment. As a professional instrument for inspecting the microstructure of metallic materials, the metallurgical microscope plays an irreplaceable role in various stages of bearing production and is a key tool for ensuring bearing quality.

I. Raw Material Quality Control

The quality of core bearing materials (such as high-carbon chromium bearing steel) directly affects the final product performance. Metallurgical microscopes are used to:

Inspect carbide distribution and morphology to ensure uniformity and fineness

Analyze non-metallic inclusion content and control it within standard ranges

Evaluate grain size to provide basis for subsequent processing

II. Production Process Optimization

By observing microstructures, key production processes are optimized:

Forging Process

Observe grain structure after forging, optimize temperature and deformation to ensure uniform grain refinement.

Heat Treatment Process

Analyze microstructure after quenching and tempering to ensure ideal balance between hardness and toughness.

III. Finished Product Quality Inspection

Before bearing delivery, metallurgical microscopes are used for key quality inspections:

- Inspect surface layer quality of raceways and rolling elements

- Detect processing defects such as grinding cracks

- Verify whether final heat treatment results meet standards

IV. Failure Analysis and Quality Improvement

When bearing failure occurs, metallurgical microscopes help analyze the causes:

Conclusion

Metallurgical microscopes provide full-process quality assurance in bearing production, from raw material inspection to finished product quality control and failure analysis. As professional bearing manufacturers, we emphasize microstructural quality control in every production stage, committed to providing customers with high-quality, long-service-life bearing products.