The radial run – out, noise, and service life of bearings during operation are 80% related to “roundness”. A roundness deviation of 0.5μm in the bearing raceway may lead to a decrease in equipment accuracy. With an ultra – high measurement accuracy of 0.01μm – 0.1μm, the roundness tester has become a core equipment for bearing factories to control roundness quality.

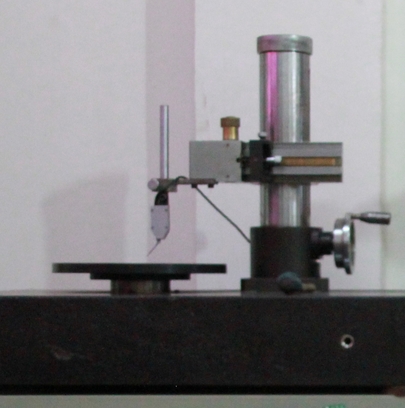

Roundness Tester

Core Applications in Bearing Production

Bearing Ring Inspection

- Raceway roundness: For high – precision bearings, it should be ≤0.005μm to avoid uneven force during operation.

- Inner/outer diameter: Detect roundness deviation to ensure the fitting accuracy with the shaft/bearing seat.

- Defect location: Identify problems such as ovality and polygonal roundness, and trace process errors.

Rolling Element Inspection

- Measurement of ball spherical/roller cylindrical roundness.

- Control of roundness deviation within the same batch: ≤0.003μm to ensure smooth operation.

- Screen out unqualified parts: Eliminate rolling elements with surface protrusions and depressions.

Advantages Compared with Other Measuring Tools

| Measuring Tool | Roundness Measurement Accuracy | Detection Efficiency | Applicable Scenarios in Bearing Factories |

|---|---|---|---|

| Dial Indicator | 0.01mm (low) | Manual reading, low efficiency | Rapid rough inspection in the workshop |

| Coordinate Measuring Machine | 0.001mm (medium) | Multi – point fitting, medium efficiency | Comprehensive detection of multiple dimensions |

| Roundness Tester | 0.01 – 0.1μm (high) | Automatic measurement + report, high efficiency | Professional precision roundness detection (core scenario) |

Usage Precautions

- Environmental Control: Maintain the temperature at 20±2℃ and humidity at 40% – 60% to avoid accuracy affected by temperature – induced deformation.

- Workpiece Fixing: It needs to be installed concentrically to ensure that the rotation center of the workpiece is consistent with the spindle of the roundness tester (deviation ≤0.02μm).

- Regular Calibration: Calibrate with a standard round bar (accuracy 0.005μm) every 3 months to ensure data accuracy.

Conclusion

For bearing factories, the roundness tester is not only a “detection tool” but also the “eyes of process optimization”. Through roundness data, it can quickly locate deviations in turning and grinding processes (such as unbalanced grinding wheels and inaccurate chuck positioning), improving bearing rotation accuracy and service life from the root. It is an essential equipment for high – end bearing production.