BNPF2045120/2RZ Backing Bearing

Technical Specifications

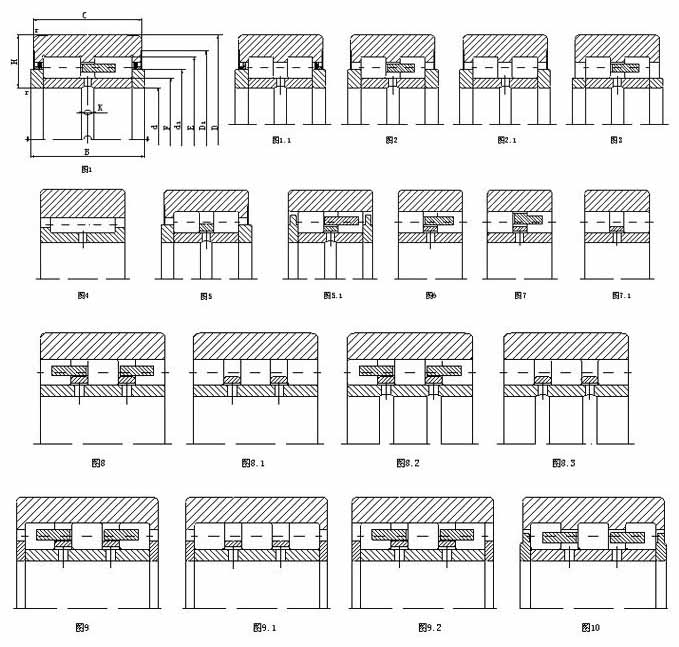

| Basic Information | ||

|---|---|---|

| Design No. (Model) | 1.1 | Design identification number or model code |

| Weight (Mass) | 28 kg | Mass (M) of the bearing, measured in kilograms (kg) |

| Boundary Dimensions (mm) | ||

| d (Inner Diameter) | 100 mm | Internal diameter of inner ring (ISO standard symbol: d) |

| D (Outer Diameter) | 225 mm | External diameter of outer ring (ISO standard symbol: D) |

| B (Width) | 120 mm | Overall width of bearing (ISO standard symbol: B) |

| C (Effective Width) | 119 mm | Effective width of roller set (ISO standard symbol: C) |

| H (Height) | 62.5 mm | Overall height of bearing assembly |

| d1 (Inner Step Diameter) | 124 mm | Diameter of inner ring step for axial location |

| D1 (Outer Step Diameter) | 183 mm | Diameter of outer ring step for housing fit |

| E (Mounting Dimension) | 163.5 mm | Effective bearing center distance for mounting |

| F (Positioning Dimension) | 119.5 mm | Axial positioning dimension for bearing seats |

| rmin (Chamfer Radius) | 2 mm | Minimum fillet radius for chamfered edges |

| K (Roller Factor) | 6 | Factor for effective roller length calculation |

| N* (Roller Quantity) | 6 | Number of rollers in bearing assembly |

| Basic Load Rating (kN) | ||

| Cr (Dynamic Load) | 795 kN | Basic dynamic load rating (ISO 281) |

| Cor (Static Load) | 1370 kN | Basic static load rating (ISO 281) |

| Cr (Roller) | 580 kN | Dynamic load rating for roller elements |

| Cor (Roller) | 960 kN | Static load rating for roller elements |

| Cr (Radial Max) | 390 kN | Maximum radial dynamic load capacity |

| Cor (Radial Max) | 550 kN | Maximum radial static load capacity |

Superior Material & Durability

Manufactured from premium G20Cr2Ni4A carburized steel with advanced heat treatment:

- Carburized layer depth ≥2.0mm

- Surface hardness HRC60-64

- Core toughness HRC30-40

- 40% longer service life

P4-Grade Precision Engineering

Meets ISO P4/ABEC 9 standards:

- Dimensional tolerance ±2μm

- Roundness error ≤0.5μm

- Cylindricity error ≤1μm

- Surface roughness Ra≤0.025μm

- 30% reduced friction

Rigorous Quality Control

- ISO 9001 certified manufacturing

- Full dimensional inspection reports

- Hardness gradient testing

- Dynamic performance evaluation

- 100% factory inspection

Typical Applications

Metal Processing & Steel Industry

- Hot/cold rolling mill support bearings

- Ladle turret bearings

- Coiler/straightener machine bearings

Mining Equipment

- Crusher bearings

- Ball mill bearings

- Mining drill bearings

Construction Machinery

- Excavator slewing bearings

- Crane bearings

- Port machinery bearings

Power Generation

- Industrial turbine bearings

- Wind turbine gearbox bearings

- Hydroelectric generator bearings

Main Dimensions

100mm × 225mm × 120mm

Bearing Type

Precision Rating

P0 (Standard) / P6 / P5 / P4 (Higher precision for demanding applications)

Cage

Material

- GCr15 Bearing Steel (Industry-standard for high load & fatigue resistance)

- GCr15SiMn

- GCr18Mo

- G20Cr2Ni4A

Clearance

C3 (standard), customizable to C0/C2/C4/C5

Brand

WJY / OEM Available

Origin

Quality Standard

Product Description

BNPF Series Backing Bearing BNPF2045120/2RZ. BNPF series backing bearing, optimized for certain load distribution scenarios. Inner diameter: 100mm, inner diameter within 100 – 200mm, suitable for medium – sized mechanical equipment with corresponding installation space requirements. Precision grade: precision grade P4, ensuring high – accuracy rotational performance for applications requiring strict running accuracy. Material: made of G20Cr2Ni4A material, featuring excellent wear resistance, toughness and fatigue strength, suitable for harsh working conditions. It can provide reliable backing support in relevant mechanical equipment, ensuring stable operation under corresponding loads and working conditions. The manufacturer offers a Standard 12-month warranty extendable up to 18 months through authorized Jinyu distributors. OEM solutions available.

Related Products

FAQ

Our bearings come with a 12-month warranty from the date of delivery. This warranty covers any manufacturing defects under normal operating conditions. For specific applications with extreme conditions, we can provide extended warranty options upon request.

For standard models that are in stock, we can ship within 3-5 working days after receiving payment. For standard models not in stock, lead time is typically 2-3 weeks.

For customized spherical roller bearings, lead time depends on the complexity of customization and quantity, usually ranging from 4-8 weeks. We can provide a more accurate timeline after evaluating your specific requirements.

We accept various payment terms including:

- T/T (Telegraphic Transfer): 30% deposit, 70% before shipment

- L/C (Letter of Credit): Irrevocable L/C at sight

- Western Union for small orders

- Negotiable terms for long-term customers

Yes, we provide comprehensive technical support including:

- Installation guidelines and recommendations

- Lubrication selection advice

- Maintenance schedules and procedures

- Online technical consultation via email and WhatsApp

- On-site technical support can be arranged for large projects (additional fees may apply)

Yes, we specialize in producing non-standard and customized spherical roller bearings. We can manufacture according to your drawings, samples, or specific technical requirements. Our engineering team will evaluate your requirements and provide a detailed quotation including design confirmation, material selection, and production timeline.

We offer flexible shipping options to meet your needs:

- Ocean Freight: Most economical for large orders and full container loads

- Land Transport: Suitable for regional deliveries and smaller shipments

Delivery Time:

- Standard bearings: 3-5 days for in-stock items

- Custom/OEM orders: 20-35 days for production and delivery

- Exact timing depends on order quantity, customization, and destination

Contact our sales team for specific shipping quotes and delivery estimates based on your location and requirements.

Our bearing pricing is influenced by several key factors:

- Precision Grade: P0 (Standard), P6, P5, or P4 precision levels

- Raw Materials: GCr15, GCr15SiMn, GCr18Mo, or other specialty steels

- Market Factors: Raw material costs and market demand

- Order Quantity: Volume discounts available for larger orders

- Customization: Special features, coatings, or modifications

For accurate pricing, we provide customized quotes based on your specific requirements. Please submit an inquiry with your needed specifications, quantities, and any special requirements for a detailed quotation.