Product Overview

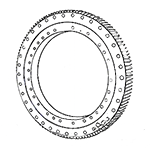

Slewing Bearings (also known as turntable bearings) are large-scale rotational components designed to handle combined axial, radial, and moment loads in heavy machinery. Our industrial slewing bearings are engineered for extreme durability in the most demanding applications.

Key Advantages of Our Slewing Bearings

- Exceptional load capacity - Simultaneously handles axial, radial and moment loads

- Precision rotation - Low friction operation with high positional accuracy

- Custom engineering - Available in diameters from 100mm to 5000mm

- Robust construction - Forged steel rings with hardened raceways

- Integrated features - Optional gear teeth, seals and mounting holes

Product Categories

Single-Row Crossed Roller Slewing Bearings

Crossed roller slewing bearings provide the highest rotational accuracy in their class. Key features: 90° crossed roller arrangement for maximum stiffness ±0.001° repeat positioning accuracy Compact design with high moment load capacity Ideal for robotics, medical equipment and telescope mounts Standard and custom clearance options available

Single-row Four Point Angular Contact Ball Slewing Bearings

Four-point contact ball slewing bearings offer versatile performance for moderate loads. Our industrial versions feature: 35° contact angle for balanced load distribution Higher speed capability than roller designs Integrated sealing systems for contaminated environments Common applications: crane slewing rings, wind turbine yaw systems Pre-lubricated for maintenance-free operation

Double-Row Step Bore Ball Slewing Bearings

Double-row ball slewing bearings deliver enhanced load capacity and rigidity. Technical highlights: Step bore design for precise axial location 45° contact angle for optimal load transfer Special raceway grinding for smooth operation Primary applications: excavator swing bearings, radar platforms Optional surface hardening up to 60 HRC

Three-Row Roller Slewing Bearings

Heavy-duty three-row roller slewing bearings represent the ultimate solution for extreme load conditions. Key specifications: Independent load paths for axial, radial and moment loads Dynamic load ratings up to 50,000kN Customizable roller diameters and lengths Essential for mining shovels, tunnel boring machines Special corrosion-resistant coatings available