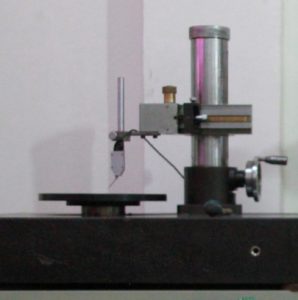

Roughness Tester: The Key to Bearing Surface Precision

In bearing manufacturing, even a 0.1μm difference in surface roughness can determine the lifespan, friction, and noise of your product. The Roughness Tester is the precision tool that ensures every bearing surface—from raceways to rolling elements—meets the strict standards your customers demand. Roughness Tester Critical Roles in Bearing Production Raceway Precision Bearings like deep groove […]