At Wafangdian JinYu Bearing Manufacturing Co., Ltd., quality isn’t an afterthought—it’s the foundation of our process. Our state-of-the-art Inspection Workshop is the heart of our commitment to delivering bearings of uncompromising precision and reliability to partners worldwide.

The Inspection Workshop is equipped with state-of-the-art tools. Coordinate Measuring Machines ensure micron-level accuracy in bearing dimensions, while Ultrasonic Flaw Detectors root out hidden internal defects. Metallurgical Microscopes allow us to fine-tune material properties at a microscopic level, and Bearing Vibration-Measuring Instruments enable us to monitor real-time performance, catching potential issues early.

Our Advanced Inspection Equipment

Dimensional Inspection Equipment

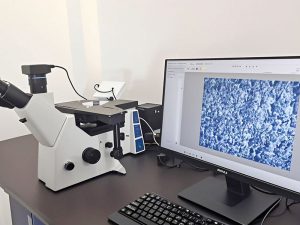

Metallurgical Microscope

Allows us to fine-tune material properties at a microscopic level.

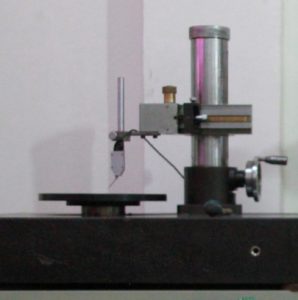

Roundness Tester

Ensures perfect circularity of bearing components for optimal performance.

One-meter length measuring instrument

Provides precise dimensional measurements for bearing components.

Roughness Tester

Measures surface texture to ensure optimal bearing performance and longevity.

Material & Performance Inspection Equipment

Dial Indicator

Provides precise measurements of small linear distances for quality control.

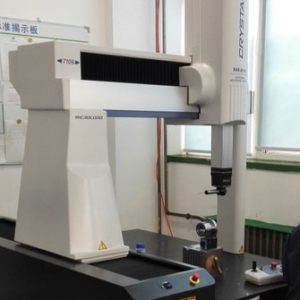

Coordinate Measuring Machine

Ensures micron-level accuracy in bearing dimensions and geometry. Critical for applications requiring absolute dimensional precision.

Ultrasonic Flaw Detector

Roots out hidden internal defects in bearing materials and components. This non-destructive testing is vital for aerospace and safety-critical applications.

Bearing Vibration Measuring Instrument

Monitors real-time performance, catching potential issues early in production. Ensures smooth, quiet operation in demanding environments.

The Human Touch: Seasoned Inspection Experts

Skilled inspectors, with over 20 years of industry experience on average, operate these instruments. They conduct rigorous checks at every production stage, from incoming materials to final products.

ISO 9001 Compliant Quality Assurance

Our strict quality control processes, aligned with ISO 9001 standards, guarantee that only the best-quality bearings leave our Wafangdian facility.

Explore More About JinYu Bearings